- Home

- Oil Rigs

- Rig Types

- Advertisers

- Desert Rigs

- Oilfield Jobs

- Jobs Offered

- Career Center

- Drilling Ships

- Petroleum Machinery and Equipment

- Oil Exploration

- Crude Oil Price

- Contract Drilling

- Fox Oilfield Services

- Global Marketing

- Overseas Markets

- Oil & Gas Equipment Manufacturers

- Heavy Duty Oil Field Trucks

- Geological & Geophysical and Dry Hole Money

- Oil Drilling Industry Membership Associations

- Government Oil & Gas Projects

- International Oil Exploration

- International Oil Production

- Fox Drilling International

- International Drilling

- Top Job Applicants

- More Top Resumes

- Job Opportunities

- Global Oil News

- Oil Investment

- Photo Gallery

- Resources

- Comments

- Contact Us

- About Us

- Sitemap

- Links

- Jobs

- Oil Tankers

- Oil & Gas Blog

- Oil & Gas Maps

- Oil & Gas Funds

- Arabian Oil & Gas

- Oil & Gas Exploration and Production Resources

- Oil & Gas Resource Links

- An Educational Oil & Gas Resources Guide

- Oil Industry References

- Bloomberg Businessweek

- Tribute to Oil Workers

- Daily News and Views

- Military Support

- Rig Construction

- More Resumes

- Post Your Resume

- Customers

- Rig Fleet

- Related Companies

- Introduce Your Company

- How to benefit from low natural gas prices

- Gasoline Prices

- Energy Technology Resources

- Resumes One

- Resumes Two

- Resumes Three

- Mining Jobs

- Job Inquiries

- Oil & Gas Bookmarks

- Jackup Rigs

- Drilling Rig Specifications

- Publish Your Resume

- Military Personnel Career & Job Placement Center

- Resume Writing Tips

- Getting A Job

- Show Yourself

- Videos

- Multimedia Page

- Ocean Oil Drilling

- Rigs For Sale

- Job Application

- Drilling Prospects

- Contract Inquiries

- Updated Job Openings

- Companies On Display

- Fox Oil & Gas Superstore

- Media Attention

- Drilling Photos

- Fox Petroleum Machinery Company

- Middle East Oil Drilling

- Oil Jobs

- Petroleum Education and Training

- Sponsors

- Favorite Travel Spots, Foods and Transportation

- Who are you and where's your rig drilling?

- Scholarships

- Announcements

- Directory Listings

- Speaking Engagements

- Friends of Fox Drilling

- Fox Exploration

- Ask Mr. Fox

Oil Industry References

Rigsworld

www.rigsworld.com

Oil & Gas Drilling Newsletter

(Free weekly Newsletter Subscription)

Rig Counts

Oil Price

Oil & Gas Trainings, Events and Conferences

News of the World

Tenders

Drilling Manual

Oil & Gas Jobs

Drilling History

Drilling Links

Offshore Fleet

Oil Rig Drilling

Features information on offshore oil rig jobs and employment within the oil drilling industry

http://oilrigdrillings.com/

Recent Posts ·

Archives

Categories

- Abandoned Oil Rigs

- Aberdeen Oil Rigs

- Atlantis Oil Rig

- Biggest Oil Rig

- Bp Oil Rig

- Bp Oil Rig Explosion

- Bp Oil Rig Fire

- Bp Oil Rig Spill

- Bp Oil Rigs

- Bp Oil Spill Animals

- Bp Oil Spill Pictures

- Bp Oil Spill Rig

- Burning Oil Rig

- Deep Horizon Oil Rig

- Deep Sea Oil Rig

- Deep Sea Oil Rigs

- Deep Water Horizon Oil Rig

- Deepwater Horizon Oil Rig

- Deepwater Oil Rig

- Deepwater Oil Rigs

- Diamond Oil Rigs

- Directional Drilling

- Drill Rig

- Drill Rigs

- Drilling

- Drilling Equipment

- Drilling For Oil

- Drilling Oil

- Drilling Oil Rigs

- Drilling Oil Wells

- Drilling Rig

- Drilling Rig Equipment

- Drilling Rig Photo

- Drilling Rig Pictures

- Drilling Rigs

- Floating Oil Rig

- Free Oil Rig Pictures

- Gas Industry

- Gulf Coast Oil Rigs

- Gulf Oil Rig

- Gulf Oil Rig Map

- Gulf Oil Rig Spill

- Gulf Oil Rigs

- Gulf Oil Spill Images

- Gulf Oil Spill Pictures

- Horizon Oil Rig

- Jack Up Oil Rig

- Land Drilling Rig Pictures

- Land Drilling Rigs

- Land Oil Rig

- Land Oil Rigs

- Largest Oil Rig

- Location Of Bp Oil Spill

- Location Of Oil Rigs

- Locations Of Oil Rigs

- Louisiana Oil Rig

- Louisiana Oil Rigs

- Map Of North Sea Oil Rigs

- Map Of Oil Rigs

- Nabors Drilling Rigs

- North Sea Oil Rigs

- North Sea Oil Rigs Map

- Ocean Oil Drilling

- Ocean Oil Rig

- Ocean Oil Rigs

- Off Shore Drilling

- Off Shore Oil

- Off Shore Oil Rig

- Off Shore Oil Rigs

- Offshore Drilling

- Offshore Drilling Rig

- Offshore Drilling Rigs

- Offshore Oil

- Offshore Oil And Gas

- Offshore Oil Drilling

- Offshore Oil Drilling Rig

- Offshore Oil Drilling Rigs

- Offshore Oil Platform

- Offshore Oil Platforms

- Offshore Oil Rig

- Offshore Oil Rig Diagram

- Offshore Oil Rig Pictures

- Offshore Oil Rigging

- Offshore Oil Rigs

- Offshore Rigging

- Offshore Rigs

- Oil & Gas

- Oil And Gas

- Oil And Gas Industry

- Oil And Gas Rigs

- Oil Drill

- Oil Drill Pictures

- Oil Drill Platform

- Oil Drill Rig

- Oil Drill Rigs

- Oil Drilling

- Oil Drilling Equipment

- Oil Drilling Offshore

- Oil Drilling Picture

- Oil Drilling Platform

- Oil Drilling Rig Pictures

- Oil Drilling Rigs

- Oil Drilling Rigs Pictures

- Oil Field

- Oil Field Photos

- Oil Field Worker

- Oil Field Workers

- Oil Industry

- Oil Pictures

- Oil Platform

- Oil Platform Locations

- Oil Platforms

- Oil Production

- Oil Production Platforms

- Oil Refinery

- Oil Rig Blowout

- Oil Rig Blowout Pictures

- Oil Rig Blowout Preventer

- Oil Rig Bp

- Oil Rig Clip Art

- Oil Rig Clipart

- Oil Rig Collapse

- Oil Rig Deepwater Horizon

- Oil Rig Design

- Oil Rig Diagram

- Oil Rig Disaster

- Oil Rig Disasters

- Oil Rig Diver

- Oil Rig Drilling

- Oil Rig Explosions

- Oil Rig Fires

- Oil Rig Fishing

- Oil Rig Helicopter

- Oil Rig Hotel

- Oil Rig Image

- Oil Rig In Gulf

- Oil Rig Leak

- Oil Rig Living Quarters

- Oil Rig Logos

- Oil Rig Map

- Oil Rig Maps

- Oil Rig Models

- Oil Rig Offshore

- Oil Rig On Fire

- Oil Rig Paintings

- Oil Rig Parts

- Oil Rig Photography

- Oil Rig Pic

- Oil Rig Picture

- Oil Rig Platform

- Oil Rig Pollution

- Oil Rig Positions

- Oil Rig Riser

- Oil Rig Roughneck

- Oil Rig Sinking

- Oil Rig Spill

- Oil Rig Spills

- Oil Rig Stickers

- Oil Rig Supply Boats

- Oil Rig Texas

- Oil Rig Tools

- Oil Rig Types

- Oil Rig Wallpaper

- Oil Rig Worker

- Oil Rig Workers

- Oil Rigs Aberdeen

- Oil Rigs In Alaska

- Oil Rigs In Gulf

- Oil Rigs In The North Sea

- Oil Rigs In Wyoming

- Oil Rigs Locations

- Oil Rigs Map

- Oil Rigs North Dakota

- Oil Rigs North Sea

- Oil Rigs Offshore

- Oil Rigs Pics

- Oil Rigs Pictures

- Oil Spill Disaster

- Oil Spill Images

- Oil Spill In Louisiana

- Oil Spill In The Ocean

- Oil Spill Pics

- Oil Spill Pictures

- Oil Spill Rig

- Oil Spills

- Oil Well Drilling

- Oil Well Drilling Rig

- Oil Well Pictures

- Oilrig

- Oilrigs

- Oklahoma Oil Rigs

- Onshore Oil Rigs

- Parts Of An Oil Rig

- Patterson Oil Rigs

- Perdido Oil Rig

- Petroleum

- Picture Oil Rig

- Pictures Of Oil Rig

- Pictures Of Oil Rigs

- Pictures Oil Rigs

- Portable Drilling Rig

- Rig Welder

- Rig Workers

- Rigs Oil

- Russian Oil Rigs

- Santa Barbara Oil Rigs

- Sea Oil Rig

- Sea Oil Rigs

- Sinking Oil Rig

- T Pain Oil Rig

- T Pain Oil Rigs

- Texas Oil Rigs

- The Deepwater Horizon Oil Rig

- Thunderhorse Oil Rig

- Toy Oil Rig

- Types Of Oil Rigs

- Uncategorized

- Underwater Oil Drilling

- Underwater Oil Rig

- Underwater Oil Rigs

- Water Drilling Rig

- Well Drilling Rig

- Work Over Rig

- Workover Rig

- Workover Rigs

- Workover Rigs For Sale

- World S Biggest Oil Rig

- World S Largest Oil Rig

From Wikipedia, the free encyclopedia

http://en.wikipedia.org/wiki/Oil_well

Oil well The creation and life of a well can be divided up into five segments:

- Planning

- Drilling

- Completion

- Production

- Abandonment

Drilling The well is created by drilling a hole 5 to 50 inches (127.0 mm to 914.4 mm) in diameter into the earth with a drilling rig that rotates a drill string with a bit attached. After the hole is drilled, sections of steel pipe (casing), slightly smaller in diameter than the borehole, are placed in the hole. Cement may be placed between the outside of the casing and the borehole. The casing provides structural integrity to the newly drilled wellbore, in addition to isolating potentially dangerous high pressure zones from each other and from the surface.

With these zones safely isolated and the formation protected by the casing, the well can be drilled deeper (into potentially more-unstable and violent formations) with a smaller bit, and also cased with a smaller size casing. Modern wells often have two to five sets of subsequently smaller hole sizes drilled inside one another, each cemented with casing.

Mud log in process, a common way to study the lithology when drilling oil wells.

To drill the well

- The drill bit, aided by the weight of thick walled pipes called "drill collars" above it, cuts into the rock. There are different types of drill bit; some cause the rock to disintegrate by compressive failure, while others shear slices off the rock as the bit turns.

- Drilling fluid, a.k.a. "mud", is pumped down the inside of the drill pipe and exits at the drill bit. Drilling mud is a complex mixture of fluids, solids and chemicals that must be carefully tailored to provide the correct physical and chemical characteristics required to safely drill the well. Particular functions of the drilling mud include cooling the bit, lifting rock cuttings to the surface, preventing destabilisation of the rock in the wellbore walls and overcoming the pressure of fluids inside the rock so that these fluids do not enter the wellbore.

- The generated rock "cuttings" are swept up by the drilling fluid as it circulates back to surface outside the drill pipe. The fluid then goes through "shakers" which strain the cuttings from the good fluid which is returned to the pit. Watching for abnormalities in the returning cuttings and monitoring pit volume or rate of returning fluid are imperative to catch "kicks" early. A "kick" is when the formation pressure at the depth of the bit is more than the hydrostatic head of the mud above, which if not controlled temporarily by closing the blowout preventers and ultimately by increasing the density of the drilling fluid would allow formation fluids and mud to come up through the annulus uncontrollably.

- The pipe or drill string to which the bit is attached is gradually lengthened as the well gets deeper by screwing in additional 30-foot (9 m) sections or "joints" of pipe under the kelly or topdrive at the surface. This process is called making a connection. Usually, joints are combined into three joints equaling one stand. Some smaller rigs only use two joints and some rigs can handle stands of four joints.

Modern driller Argentina.

Completion Completion (oil and gas wells)

After drilling and casing the well, it must be 'completed'. Completion is the process in which the well is enabled to produce oil or gas.

In a cased-hole completion, small holes called perforations are made in the portion of the casing which passed through the production zone, to provide a path for the oil to flow from the surrounding rock into the production tubing. In open hole completion, often 'sand screens' or a 'gravel pack' is installed in the last drilled, uncased reservoir section. These maintain structural integrity of the wellbore in the absence of casing, while still allowing flow from the reservoir into the wellbore. Screens also control the migration of formation sands into production tubulars and surface equipment, which can cause washouts and other problems, particularly from unconsolidated sand formations of offshore fields.

After a flow path is made, acids and fracturing fluids are pumped into the well to fracture, clean, or otherwise prepare and stimulate the reservoir rock to optimally produce hydrocarbons into the wellbore. Finally, the area above the reservoir section of the well is packed off inside the casing, and connected to the surface via a smaller diameter pipe called tubing. This arrangement provides a redundant barrier to leaks of hydrocarbons as well as allowing damaged sections to be replaced. Also, the smaller crossectional area of the tubing produces reservoir fluids at an increased velocity in order to minimize liquid fallback that would create additional back pressure, and shields the casing from corrosive well fluids.

In many wells, the natural pressure of the subsurface reservoir is high enough for the oil or gas to flow to the surface. However, this is not always the case, especially in depleted fields where the pressures have been lowered by other producing wells, or in low permeability oil reservoirs. Installing a smaller diameter tubing may be enough to help the production, but artificial lift methods may also be needed. Common solutions include downhole pumps, gas lift, or surface pump jacks. Many new systems in the last ten years have been introduced for well completion. Multiple packer systems with frac ports or port collars in an all in one system have cut completion costs and improved production, especially in the case of horizontal wells. These new systems allow casings to run into the lateral zone with proper packer/frac port placement for optimal hydrocarbon recovery.

Production The production stage is the most important stage of a well's life, when the oil and gas are produced. By this time, the oil rigs and workover rigs used to drill and complete the well have moved off the wellbore, and the top is usually outfitted with a collection of valves called a Christmas tree or Production trees. These valves regulate pressures, control flows, and allow access to the wellbore in case further completion work is needed. From the outlet valve of the production tree, the flow can be connected to a distribution network of pipelines and tanks to supply the product to refineries, natural gas compressor stations, or oil export terminals.

As long as the pressure in the reservoir remains high enough, the production tree is all that is required to produce the well. If the pressure depletes and it is considered economically viable, an artificial lift method mentioned in the completions section can be employed.

Workovers are often necessary in older wells, which may need smaller diameter tubing, scale or paraffin removal, acid matrix jobs, or completing new zones of interest in a shallower reservoir. Such remedial work can be performed using workover rigs – also known as pulling units or completion rigs – to pull and replace tubing, or by the use of well intervention techniques utilizing coiled tubing. Depending on the type of lift system and wellhead a rod rig or flushby can be used to change a pump without pulling the tubing.

Enhanced recovery methods such as water flooding, steam flooding, or CO2 flooding may be used to increase reservoir pressure and provide a "sweep" effect to push hydrocarbons out of the reservoir. Such methods require the use of injection wells (often chosen from old production wells in a carefully determined pattern), and are used when facing problems with reservoir pressure depletion, high oil viscosity, or can even be employed early in a field's life. In certain cases – depending on the reservoir's geomechanics – reservoir engineers may determine that ultimate recoverable oil may be increased by applying a waterflooding strategy early in the field's development rather than later. Such enhanced recovery techniques are often called "tertiary recovery".

Abandonment A well is said to reach an "economic limit" when its most efficient production rate does not cover the operating expenses, including taxes.[5]

The economic limit for oil and gas wells can be expressed using these formula:

Oil fields:

Gas fields:

Where:

is an oil well's economic limit in oil barrels per month (bbls/month).

is a gas well's economic limit in thousand standard cubic feet per month (MSCF/month).

are the current prices of oil and gas in dollars per barrels and dollars per MSCF respectively.

is the lease operating expenses in dollars per well per month.

working interest, as a fraction.[6]

net revenue interest, as a fraction.

gas/oil ratio as bbls/MSCF.

condensate yield as barrel/million standard cubic feet.

production and severance taxes, as a fraction.

[5]

When the economic limit is raised, the life of the well is shortened and proven oil reserves are lost. Conversely, when the economic limit is lowered, the life of the well is lengthened.

When the economic limit is reached, the well becomes a liability and is abandoned. In this process, tubing is removed from the well and sections of well bore are filled with cement to isolate the flow path between gas and water zones from each other, as well as the surface. Completely filling the well bore with cement is costly and unnecessary. The surface around the wellhead is then excavated, and the wellhead and casing are cut off, a cap is welded in place and then buried.

At the economic limit there often is still a significant amount of unrecoverable oil left in the reservoir. It might be tempting to defer physical abandonment for an extended period of time, hoping that the oil price will go up or that new supplemental recovery techniques will be perfected. However, lease provisions and governmental regulations usually require quick abandonment; liability and tax concerns also may favor abandonment.

In theory an abandoned well can be reentered and restored to production (or converted to injection service for supplemental recovery or for downhole hydrocarbons storage), but reentry often proves to be difficult mechanically and not cost effective.

Types of wells

A natural gas well in the southeast Lost Hills Field, California, US.

Fossil-fuel wells come in many varieties. By produced fluid, there can be wells that produce oil, wells that produce oil and natural gas, or wells that only produce natural gas. Natural gas is almost always a byproduct of producing oil, since the small, light gas carbon chains come out of solution as they undergo pressure reduction from the reservoir to the surface, similar to uncapping a bottle of soda pop where the carbon dioxide effervesces. Unwanted natural gas can be a disposal problem at the well site. If there is not a market for natural gas near the wellhead it is virtually valueless since it must be piped to the end user. Until recently, such unwanted gas was burned off at the wellsite, but due to environmental concerns this practice is becoming less common.[citation needed] Often, unwanted (or 'stranded' gas without a market) gas is pumped back into the reservoir with an 'injection' well for disposal or repressurizing the producing formation. Another solution is to export the natural gas as a liquid.[7] Gas-to-liquid, (GTL) is a developing technology that converts stranded natural gas into synthetic gasoline, diesel or jet fuel through the Fischer-Tropsch process developed in World War II Germany. Such fuels can be transported through conventional pipelines and tankers to users. Proponents claim GTL fuels burn cleaner than comparable petroleum fuels. Most major international oil companies are in advanced development stages of GTL production, e.g. the 140,000 bbl/d (22,000 m3/d) Pearl GTL plant in Qatar, scheduled to come online in 2011. In locations such as the United States with a high natural gas demand, pipelines are constructed to take the gas from the wellsite to the end consumer.

Another obvious way to classify oil wells is by land or offshore wells. There is very little difference in the well itself. An offshore well targets a reservoir that happens to be underneath an ocean. Due to logistics, drilling an offshore well is far more costly than an onshore well. By far the most common type is the onshore well. These wells dot the Southern and Central Great Plains, Southwestern United States, and are the most common wells in the Middle East.

Another way to classify oil wells is by their purpose in contributing to the development of a resource. They can be characterized as:

- wildcat wells are those drilled outside of and not in the vicinity of known oil or gas fields.

- exploration wells are drilled purely for exploratory (information gathering) purposes in a new area.

- appraisal wells are used to assess characteristics (such as flow rate) of a proven hydrocarbon accumulation.

- production wells are drilled primarily for producing oil or gas, once the producing structure and characteristics are determined.

- oil producers producing predominantly liquid hydrocarbons, but mostly with some associated gas.

- gas producers producing almost entirely gaseous hydrocarbons.

- water injectors injecting water into the formation to maintain reservoir pressure, or simply to dispose of water produced with the hydrocarbons because even after treatment, it would be too oily and too saline to be considered clean for dumping overboard offshore, let alone into a fresh water resource in the case of onshore wells. Water injection into the producing zone frequently has an element of reservoir management; however, often produced water disposal is into shallower zones safely beneath any fresh water zones.

- aquifer producers intentionally producing water for re-injection to manage pressure. If possible this water will come from the reservoir itself. Using aquifer produced water rather than water from other sources is to preclude chemical incompatibility that might lead to reservoir-plugging precipitates. These wells will generally needed only if produced water from the oil or gas producers is insufficient for reservoir management purposes.

- gas injectors injecting gas into the reservoir often as a means of disposal or sequestering for later production, but also to maintain reservoir pressure.

- New Field Wildcat (NFW) – far from other producing fields and on a structure that has not previously produced.

- New Pool Wildcat (NPW) – new pools on already producing structure.

- Deeper Pool Test (DPT) – on already producing structure and pool, but on a deeper pay zone.

- Shallower Pool Test (SPT) – on already producing structure and pool, but on a shallower pay zone.

- Outpost (OUT) – usually two or more locations from nearest productive area.

- Development Well (DEV) – can be on the extension of a pay zone, or between existing wells (Infill).

The daily rates of offshore drilling rigs vary by their capability, and the market availability. Rig rates reported by industry web service[8] show that the deepwater water floating drilling rigs are over twice that of the shallow water fleet, and rates for jackup fleet can vary by factor of 3 depending upon capability.

With deepwater drilling rig rates in 2010 of around $420,000/day,[8] and similar additional spread costs, a deep water well of duration of 100 days can cost around US$100 million.

With high performance jackup rig rates in 2010 of around $150,000,[8] and similar service costs, a high pressure, high temperature well of duration 100 days can cost about US$30 million.

Onshore wells can be considerably cheaper, particularly if the field is at a shallow depth, where costs range from less than $1 million to $15 million for deep and difficult wells.[citation needed]

The total cost of an oil well mentioned does not include the costs associated with the risk of explosion and leakage of oil. Those costs include the cost of protecting against such disasters, the cost of the cleanup effort, and the hard-to-calculate cost of damage to the company's image.

Reefs

This section requires expansion.

Offshore platforms (the structure supporting the wells) often provide habitat for marine life. After the wells have been abandoned, sometimes the platforms can be toppled in place or dropped to the ocean floor elsewhere to produce artificial reefs.[citation needed]

See also References 1. ^ ASTM timeline of oil

2. ^ a b Joseph P. Riva Jr. and Gordon I. Atwater. "petroleum". Encyclopædia Britannica. Retrieved 2008-06-30.

3. ^ Dr. Kasem Ajram (1992). The Miracle of Islam Science (2nd Edition ed.). Knowledge House Publishers. ISBN 0-911119-43-4.

4. ^ Zayn Bilkadi (University of California, Berkeley), "The Oil Weapons", Saudi Aramco World, January–February 1995, pp. 20–7

5. ^ a b Mohammed A. Mian, Petroleum Engineering Handbook for the Practicing Engineer, Tulsa, Okla.: PennWell, 1992, p.447.

6. ^ Oilfield Glossary - "working interest"

7. ^ Gas to liquid

8. ^ a b c Rigzone - Rig day rates : http://www.rigzone.com/data/dayrates/

External links

- Schlumberger Oilfield Glossary

- The History of the Oil Industry

- "Black Gold" Popular Mechanics, January 1930 - large photo article on oil drilling in the 1920s and 1930s

- "World's Deepest Well" Popular Science, August 1938, article on the late 1930s technology of drilling oil wells

How Oil Drilling Works

by Craig C. Freudenrich, Ph.D.

(http://science.howstuffworks.com/oil-drilling.htm/)

Oil Exploration

Oil is a fossil fuel that can be found in many countries around the world. In this section, we will discuss how oil is formed and how geologists find it.

Forming Oil

Oil is formed from the remains of tiny plants and animals (plankton) that died in ancient seas between 10 million and 600 million years ago. After the organisms died, they sank into the sand and mud at the bottom of the sea.

Photo courtesy Institute of Petroleum

Oil forms from dead organisms in ancient seas.

(Click here for a larger image.)

Close-up of reservoir rock

(oil is in black)

Over the years, the organisms decayed in the sedimentary layers. In these layers, there was little or no oxygen present. So microorganisms broke the remains into carbon-rich compounds that formed organic layers. The organic material mixed with the sediments, forming fine-grained shale, or source rock. As new sedimentary layers were deposited, they exerted intense pressure and heat on the source rock. The heat and pressure distilled the organic material into crude oil and natural gas. The oil flowed from the source rock and accumulated in thicker, more porous limestone or sandstone, called reservoir rock. Movements in the Earth trapped the oil and natural gas in the reservoir rocks between layers of impermeable rock, or cap rock, such as granite or marble.

Oil reservoir rocks (red) and natural gas (blue) can be trapped by folding (left), faulting (middle) or pinching out (right).

These movements of the Earth include:

- Folding - Horizontal movements press inward and move the rock layers upward into a fold or anticline.

- Faulting - The layers of rock crack, and one side shifts upward or downward.

- Pinching out - A layer of impermeable rock is squeezed upward into the reservoir rock.

The task of finding oil is assigned to geologists, whether employed directly by an oil company or under contract from a private firm. Their task is to find the right conditions for an oil trap -- the right source rock, reservoir rock and entrapment. Many years ago, geologists interpreted surface features, surface rock and soil types, and perhaps some small core samples obtained by shallow drilling. Modern oil geologists also examine surface rocks and terrain, with the additional help of satellite images. However, they also use a variety of other methods to find oil. They can use sensitive gravity meters to measure tiny changes in the Earth's gravitational field that could indicate flowing oil, as well as sensitive magnetometers to measure tiny changes in the Earth's magnetic field caused by flowing oil. They can detect the smell of hydrocarbons using sensitive electronic noses called sniffers. Finally, and most commonly, they use seismology, creating shock waves that pass through hidden rock layers and interpreting the waves that are reflected back to the surface.

Searching for oil over water using seismology

In seismic surveys, a shock wave is created by the following:

- Compressed-air gun - shoots pulses of air into the water (for exploration over water)

- Thumper truck - slams heavy plates into the ground (for exploration over land)

- Explosives - drilled into the ground (for exploration over land) or thrown overboard (for exploration over water), and detonated

Although modern oil-exploration methods are better than previous ones, they still may have only a 10-percent success rate for finding new oil fields. Once a prospective oil strike is found, the location is marked by GPS coordinates on land or by marker buoys on water.

Preparing to Drill

Once the site has been selected, it must be surveyed to determine its boundaries, and environmental impact studies may be done. Lease agreements, titles and right-of way accesses for the land must be obtained and evaluated legally. For off-shore sites, legal jurisdiction must be determined.

Once the legal issues have been settled, the crew goes about preparing the land:

- The land is cleared and leveled, and access roads may be built.

- Because water is used in drilling, there must be a source of water nearby. If there is no natural source, they drill a water well.

- They dig a reserve pit, which is used to dispose of rock cuttings and drilling mud during the drilling process, and line it with plastic to protect the environment. If the site is an ecologically sensitive area, such as a marsh or wilderness, then the cuttings and mud must be disposed offsite -- trucked away instead of placed in a pit.

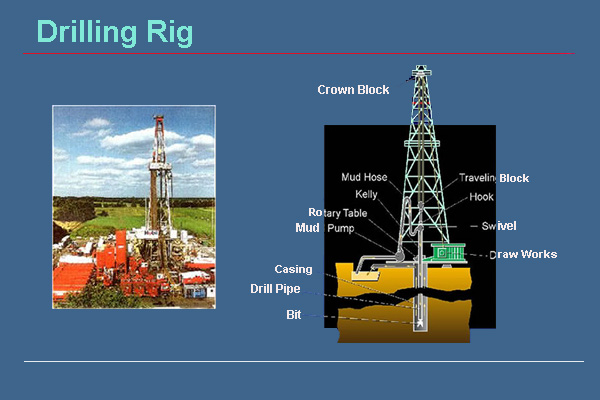

Setting Up the Rig

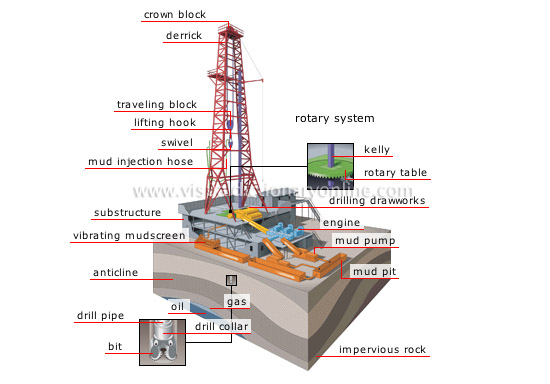

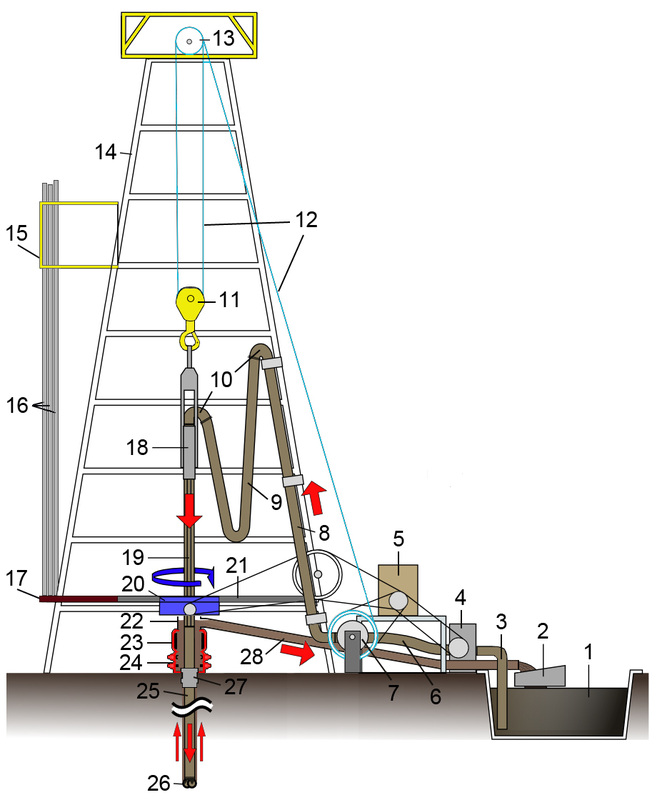

Depending upon the remoteness of the drill site and its access, equipment may be transported to the site by truck, helicopter or barge. Some rigs are built on ships or barges for work on inland water where there is no foundation to support a rig (as in marshes or lakes). Once the equipment is at the site, the rig is set up. Here are the major systems of a land oil rig:

Anatomy of an oil rig

- Power system

- large diesel engines - burn diesel-fuel oil to provide the main source of power

- electrical generators - powered by the diesel engines to provide electrical power

- Mechanical system - driven by electric motors

- hoisting system - used for lifting heavy loads; consists of a mechanical winch (drawworks) with a large steel cable spool, a block-and-tackle pulley and a receiving storage reel for the cable

- turntable - part of the drilling apparatus

- Rotating equipment - used for rotary drilling

- swivel - large handle that holds the weight of the drill string; allows the string to rotate and makes a pressure-tight seal on the hole

- kelly - four- or six-sided pipe that transfers rotary motion to the turntable and drill string

- turntable or rotary table - drives the rotating motion using power from electric motors

- drill string - consists of drill pipe (connected sections of about 30 ft / 10 m) and drill collars (larger diameter, heavier pipe that fits around the drill pipe and places weight on the drill bit)

- drill bit(s) - end of the drill that actually cuts up the rock; comes in many shapes and materials (tungsten carbide steel, diamond) that are specialized for various drilling tasks and rock formations

- Casing - large-diameter concrete pipe that lines the drill hole, prevents the hole from collapsing, and allows drilling mud to circulate

Mud circulation in the hole

- Circulation system - pumps drilling mud (mixture of water, clay, weighting material and chemicals, used to lift rock cuttings from the drill bit to the surface) under pressure through the kelly, rotary table, drill pipes and drill collars

- pump - sucks mud from the mud pits and pumps it to the drilling apparatus

- pipes and hoses - connects pump to drilling apparatus

- mud-return line - returns mud from hole

- shale shaker - shaker/sieve that separates rock cuttings from the mud

- shale slide - conveys cuttings to the reserve pit

- reserve pit - collects rock cuttings separated from the mud

- mud pits - where drilling mud is mixed and recycled

- mud-mixing hopper - where new mud is mixed and then sent to the mud pits

Drill-mud circulation system

- Derrick - support structure that holds the drilling apparatus; tall enough to allow new sections of drill pipe to be added to the drilling apparatus as drilling progresses

- Blowout preventer - high-pressure valves (located under the land rig or on the sea floor) that seal the high-pressure drill lines and relieve pressure when necessary to prevent a blowout (uncontrolled gush of gas or oil to the surface, often associated with fire)

Drilling

Rotary workers trip drill pipe

The crew sets up the rig and starts the drilling operations. First, from the starter hole, they drill a surface hole down to a pre-set depth, which is somewhere above where they think the oil trap is located. There are five basic steps to drilling the surface hole:

- Place the drill bit, collar and drill pipe in the hole.

- Attach the kelly and turntable and begin drilling.

- As drilling progresses, circulate mud through the pipe and out of the bit to float the rock cuttings out of the hole.

- Add new sections (joints) of drill pipes as the hole gets deeper.

- Remove (trip out) the drill pipe, collar and bit when the pre-set depth (anywhere from a few hundred to a couple-thousand feet) is reached.

The casing crew puts the casing pipe in the hole. The cement crew pumps cement down the casing pipe using a bottom plug, a cement slurry, a top plug and drill mud. The pressure from the drill mud causes the cement slurry to move through the casing and fill the space between the outside of the casing and the hole. Finally, the cement is allowed to harden and then tested for such properties as hardness, alignment and a proper seal.

New Drilling Technologies

The U.S. Department of Energy and the oil industry are working on new ways to drill oil, including horizontal drilling techniques, to reach oil under ecologically-sensitive areas, and using lasers to drill oil wells.

Drilling continues in stages: They drill, then run and cement new casings, then drill again. When the rock cuttings from the mud reveal the oil sand from the reservoir rock, they may have reached the final depth. At this point, they remove the drilling apparatus from the hole and perform several tests to confirm this finding:

- Well logging - lowering electrical and gas sensors into the hole to take measurements of the rock formations there

- Drill-stem testing - lowering a device into the hole to measure the pressures, which will reveal whether reservoir rock has been reached

- Core samples - taking samples of rock to look for characteristics of reservoir rock

In the movies, you see oil gushing (a blowout), and perhaps even a fire, when drillers reach the final depth. These are actually dangerous conditions, and are (hopefully) prevented by the blowout preventer and the pressure of the drilling mud. In most wells, the oil flow must be started by acidizing or fracturing the well.

Once they have reached the final depth, the crew completes the well to allow oil to flow into the casing in a controlled manner. First, they lower a perforating gun into the well to the production depth. The gun has explosive charges to create holes in the casing through which oil can flow. After the casing has been perforated, they run a small-diameter pipe (tubing) into the hole as a conduit for oil and gas to flow up the well. A device called a packer is run down the outside of the tubing. When the packer is set at the production level, it is expanded to form a seal around the outside of the tubing. Finally, they connect a multi-valved structure called a Christmas tree to the top of the tubing and cement it to the top of the casing. The Christmas tree allows them to control the flow of oil from the well.

Once the well is completed, they must start the flow of oil into the well. For limestone reservoir rock, acid is pumped down the well and out the perforations. The acid dissolves channels in the limestone that lead oil into the well. For sandstone reservoir rock, a specially blended fluid containing proppants (sand, walnut shells, aluminum pellets) is pumped down the well and out the perforations. The pressure from this fluid makes small fractures in the sandstone that allow oil to flow into the well, while the proppants hold these fractures open. Once the oil is flowing, the oil rig is removed from the site and production equipment is set up to extract the oil from the well.

Extracting the Oil

After the rig is removed, a pump is placed on the well head.

Pump on an oil well

In the pump system, an electric motor drives a gear box that moves a lever. The lever pushes and pulls a polishing rod up and down. The polishing rod is attached to a sucker rod, which is attached to a pump. This system forces the pump up and down, creating a suction that draws oil up through the well.

In some cases, the oil may be too heavy to flow. A second hole is then drilled into the reservoir and steam is injected under pressure. The heat from the steam thins the oil in the reservoir, and the pressure helps push it up the well. This process is called enhanced oil recovery.

Enhanced oil recovery

With all of this oil-drilling technology in use, and new methods in development, the question remains: Will we have enough oil to meet our needs? Current estimates suggest that we have enough oil for about 63 to 95 years to come, based on current and future finds and present demands.

Home

About Us

Oil Rigs

Resumes

Rig Fleet

Rig Types

Oil Maps

Desert Rigs

Oilfield Jobs

Jobs Offered

Drilling Ships

Made in USA

Oil Exploration

Contract Drilling

Oilfield Services

American Greats

American Heroes

Global Marketing

Overseas Markets

Oil & Gas Equipment

Manufacturers

Heavy Duty Oil Field

Trucks

Geological & Geophysical

and Dry Hole Money

Oil Drilling Industry

Membership Associations

Government Oil & Gas Projects

International Oil Exploration

International Oil Production

Fox Drilling International

International Drilling

Charitable Projects

Top Job Applicants

Job Opportunities

Global Oil News

Oil Investment

Photo Gallery

Resources

Favorites

Comments

Contact Us

Sitemap

Links

Jobs

Oil Tankers

Oil & Gas Blog

Oil & Gas Maps

Oil & Gas Funds

Arabian Oil & Gas

Oil & Gas Exploration and

Production Resources

Oil & Gas Resource Links

Oil Industry References

Bloomberg Businessweek

Tribute to Oil Workers

Daily News and Views

Military Support

Rig Construction

More Resumes

Customers

Rig Fleet